News 14 April 2011

A section of the bent wing attachment structure was replaced a few days ago. Reinforcements are still to be welded on to the splice, but structural integrity is re-established and this allowed us to remove the fuselage frame from the jig. Arild Tveit had to cut parts of the jig with an angle grinder to free it from the fuselage. One of the big challenges on the project seems to be solved.

The grinding took place outside to prevent dust and fire hazard.

Small funny details on the fuel filter (Filterbrandhahn)

Assembly of the landing gear can begin (axels and lower part of the legs).

News 12 January 2011

The restoration of parts and subassemblies continues in parallel with work on the fuselage frame. A serious distortion of the left wing aft attachment made it necessary to construct a jig. The next project update will hopefully be when the jig is completed.

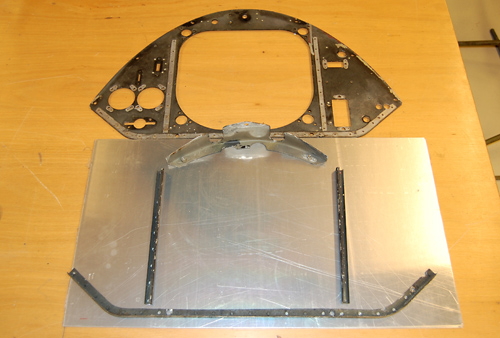

At one time somebody made an unoriginal instrument panel. A sheet of 2 mm aluminum is the first step towards the reconstruction of an original instrument panel.

The Compass (Fl 23233) was dry as a desert with faded numbers. Thorough cleaning, touch-up of numbers, compass oil and some paint was all that was needed.

Der kleinen Linsenlafette LL-K was salvaged from an outdoor WW II wreckage. Remove some corrosion, change a few bearings and produce a few small pars is all that is needed to bring it in working condition. And of cause, the Plexiglas cupola has to be made.

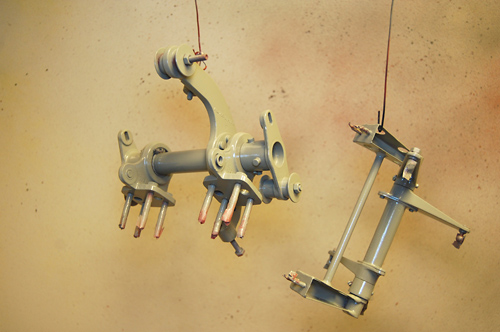

Hanging to dry in the paint box: Elevator center hinge (left) and firewall throttle/mixture bellcrank (right)

News 1 June 2010

Finally, the third and last museum engine is ready for delivery to the Air Force Museum in Bodø. From now on we can focus on flyable Storch-parts only. Good news is that only neglectable amounts of corrosion were found internally in the fuselage frame during x-ray. A few minor cracks discovered will be welded later. As can be seen at the picture below, the first airworthy parts are ready for installation.

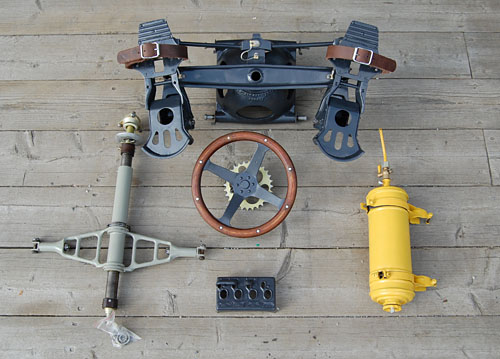

Tail plane trim actuator, rudder pedals, elevator trim wheel, circuit breaker housing and primer fuel tank ready for installation.

News 17 February 2010

Focus is now set on the fuselage. First we removed the old fabric. Later we removed all items attached to the fuselage frame. When necessary a lot of items were documented by measurements and photos. The shelves are now full of everything from wooden stringers, tubes and control roods to rudder pedals and instruments. It is fun to note that the majority of parts are original German-ones and not substitutes replaced during the service in France. Today, the fuselage frame was transported to the Air Force Base at Kjeller for x-raying. Further work is dependent on the amount of corrosion found internally in the fuselage tubes. Parallel to this work we have started to restore items that are to be reinstalled onto the fuselage frame. We will also do some preparations for the engine overhaul.

The naked fuselage frame in the x-ray room at the Air Force Base.

The identification tag riveted to the fuselage frame tail section stating 156 and Werk nr. 1816

News 8 December 2009

A milestone was reached 12 November when engine # 1 & 2 was delivered to the Sola Aviation Museum. We changed engines on Storch SB+UY the following day. It is many years since anybody has done something similar on a Storch in Norway. Engine # 2 was left in the hangar for static display until it is needed for the Arado Ar 66 restoration. After a cheerful weekend at Sola, we headed home with engine Wnr. 4480104 at the trailer.

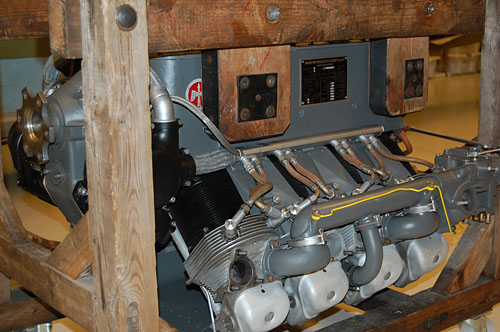

Engine # 2 installed in an Arado Ar 66 engine mount and ready for delivery

to the Sola Aviation Museum.

Engine change at Sola. Engine Wnr. 4480104 to the left.

Behind engine # 1 is the fuselage frame from an Arado 196 that once was on board the sunken heavy cruiser Blücher.

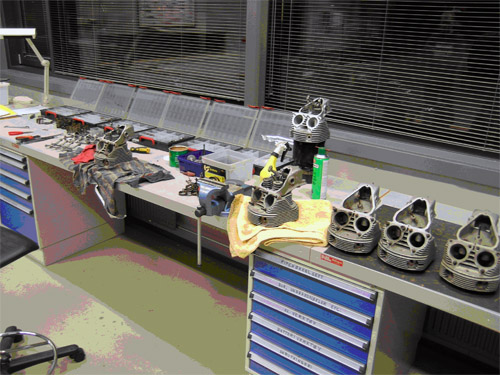

Back at the workshop in Fetsund we immediately started to disassemble engine Wnr. 4480104. The engine seems to be in good condition with little corrosion and wear.

The first step is to get a good picture of what needs to be replaced and what work has to be done. At the moment we are measuring and inspecting parts.

The fourth Argus engine during disassembly in the workshop

News 26 August 2009

Engine # 1 is installed in its transport dolly ready for delivery. We have promised to deliver engine # 2 complete with Arado Ar 66 engine mounts. Our next task is therefore to make engine mounts.

Engine # 1 in its transport dolly.

Engine # 1 in its transport dolly.

News 25 April 2009

The whole Storch restoration team went to Speyer in Germany to visit the old aircraft part market arranged 18 April. The hunt for parts resulted in an increased baggage weight on the return flight. A generator, a dual pressure indicator and a fuel pump being the most significant items acquired. We also got some most sought for cowling parts. The market was a great place to meet likeminded people.

We met "Mr. Argus", Dirk Bende and his team at Speyer.The progress on the engines is steady. All the major components are installed and smaller details will be in focus for the next months. Major challenges are the clips securing the spark plug connectors and making missing baffle plates. The present result is almost unbelievable when compared with the condition of the engine in 1994.

Engine # 3. We keep the engines inverted until they are almost finished.

Engine # 3 as found outdoors in 1994

News 18 January 2009Finally, the engines look like engines again. All 24 cylinders are installed permanently and the oil system is nearly complete. Although it might look like the engines are nearly finished, they are far from that. A lot of details on the ignition system, induction system and pneumatic starting system need attention. Further, all the baffling is in a rather sorry state. To get an impression of the final result, the baffling for Storch Werknr. 1816 is temporarily installed on engine # 2 (in the middle).

The three engines. From left # 1, 2 and 3

News 26 October 2008

The three engines being restored are:

Wnr. 4445848 which will in principle be made runable. It originates from a Fw 58 that crashed in Norway during World War II. It is in-house given the designation: Engine # 1.

Wnr. 4447758 will be complete, but at a lower standard. It originates from an Ar 66 that crashed near Kirkenes in Norway during World War II. It is in-house given the designation:

Engine # 2.Wnr. 4450797 will be externally complete, but without a few internal components. It originates from a Go 145 that crashed near Kirkenes in Norway during World War II.

It is in-house given the designation: Engine # 3.At first glance the engines might look as they did in March 2008. However, engine # 1 has been through a total rework of the crankshaft, bearings and connecting rods. On engine # 3 the crankshaft, camshaft and oil pump is installed. Further all crankcase components are primed and ready for painting.

The three engines. From left # 1, 2 and 3We decided that a proper workshop also must include a small museum. A cabinet was placed in a corner and a few shelves set aside for the purpose. The displayed items mainly originate from airplanes that fought the air battle between British and German airplanes in the Lake Lesjaskog area in April 1940.

The museum corner. A lot of the items on the picture can be sold or traded

to support the Storch restoration.

News 29 March 2008The workshop is ready! It became nicer than expected, but it required a lot more work than feared when we started. We can now resume work on the three static Argus engines.

The “workforce” and the three Argus engines in the new workshop.

From left: Arild Tveit, Tor Nørstegård, Eivind Svenningsen, Harald Holm and Torstein Walseth.

The coffee break corner

News 7 November 2007:

The Storch arrived Fetsund safely after a long journey from Carson City, USA. With the help of friends the fuselage, wings and several boxes were offloaded from the 40 ft container and moved into the workshop. The workshop is not completed yet and more winter isolation of walls and a new ceiling must be installed before the Storch restoration can continue.

The Storch entering its new nest.

News 3 May 2007:

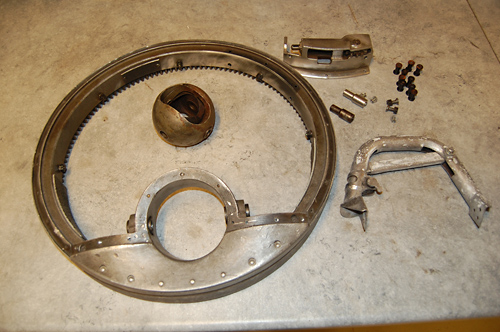

Finally, all 24 cylinders are restored and ready for installation on the engines. All parts are original down to the smallest washer and nut. It was however necessary to replace a few parts that has suffered too much from years outside in the Norwegian mountains. Luckily, our stock contains unserviceable parts that suits perfect in a static engine. Although meant for museums, all except a few cylinders are in runable condition. The focus is now on the three crankcases. One of them has considerable surface corrosion that need to be treated. It was a challenge to restore a fragmented accessory drive gearbox (Hinter Deckel, Teil Nr. 1557). One front bearing housing (Lagergehäuse, Teil Nr. 1130) is totally missing.

At week 19 the focus will change towards preparing the future Storch workshop. The work on the building is delayed and will take approximately six months. It will be a pause in the restoration work in that period.

24 cylinders in front of two crankcases.

The Hinter Deckel ready for painting and installation of finer details.

News 24 February 2007:

The process of restoring three static Argus As 10C engines for display has started. The first batch of 16 cylinder heads are in the assembly line. Corroded parts are subject to glass bead blasting prior to installation. The goal is to make most of the cylinder heads runable although not flyable.

Cylinder head assembly line.

News 17 December 2006:

The process of sorting out all the Argus spare parts is nearly completed.

Parts down to the smallest nut, washer and bushing are organized logically

in separate boxes. Parts from the two disassembled engines are being cleaned

and organized the same way. This is at present going on in a hangar at

Kjeller, but hopefully work on the permanent workshop can start in January

2007.

News 18 October 2006:

Three big wooden boxes with Argus As 10C spare parts arrived 9 October 2006. The boxes contain all types of spare parts except main crankcases, crankshafts and camshafts. Some parts are damaged or worn out, others airworthy or new.

All the parts will be cleaned inspected and catalogued. The intentions are to put aside a small number of serviceable parts for the Norwegian Storch project. Further, a number of unserviceable parts are needed for the restoration of three static display engines.

The remaining parts will be traded or sold. A list of parts will later be made available on the Surplus Parts side. However, if parts are needed today, please do not hesitate to contact us.

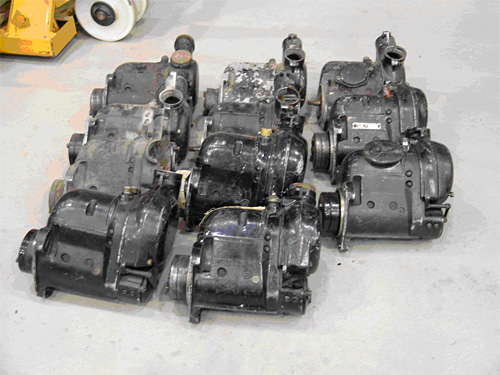

The lot contains large quantity of gaskets and O-rings.

In the background two propeller hubs (Luftschraubennabe).

11 magnetos, 6 Bosch GE 8 BLS 137 and 5 Bosch GE 8 BRS 136.

The plan is to make at least four of them serviceable.